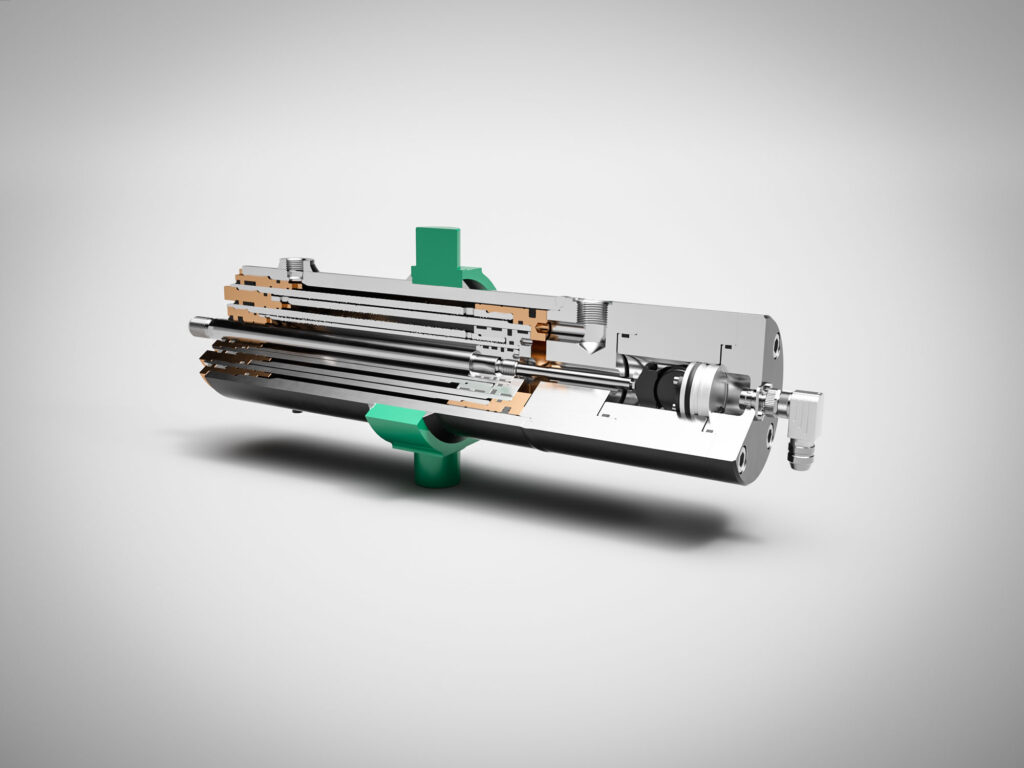

Synchronous cylinder

Synchronous cylinder

Synchronous cylinder > Synchronous cylinder

Good to know: Here we have further developed the ZT 212 double-acting telescopic cylinder series in response to increased customer demand.

| Nominal pressure: | 120 bar (12 MPa) |

| Static test pressure: | 180 bar (18 MPa) |

| Piston diameter: | 63 – 140 mm (others possible on request) |

| Temperature range | -20 °C … +80 °C (through hydraulic fluid) |

| Viscosity range: | (10 … 600) 10-6 m²/s |

| Lifting speed: | 0 – 0,5 m/s |

| Operating medium: | Mineral oil according to DIN 51524, HFD fluids |

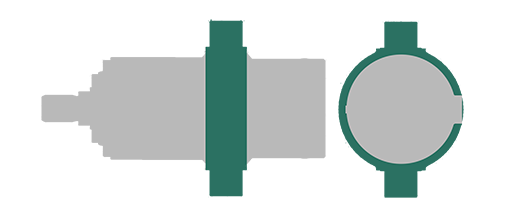

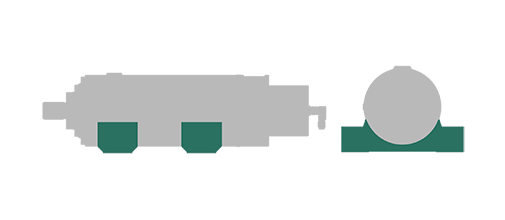

Befestigungsarten

Good to know: The telescopic cylinders are available in double-acting and single-acting versions.

| Nominal pressure: | 120 bar (12 MPa) |

| Static test pressure: | 180 bar (18 MPa) |

| Piston diameter: | 32 – 280 mm |

| Temperature range: | -20…+80 °C |

| Viscosity range: | 10…600 mm/s² |

| Lifting speed: | 0-0,5 m/s |

| Operating medium: | Mineral oil according to DIN 51524, HFD fluids HFA, HFB and HFC fluids by special designs |

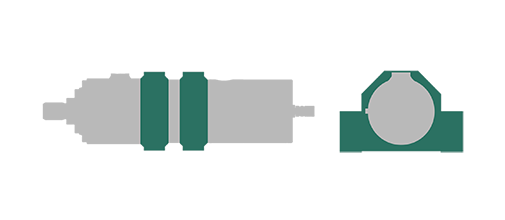

Befestigungsarten

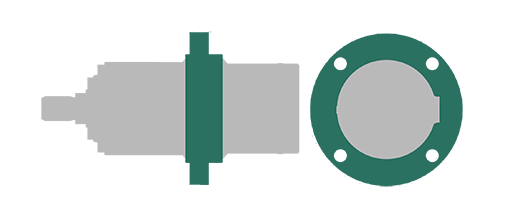

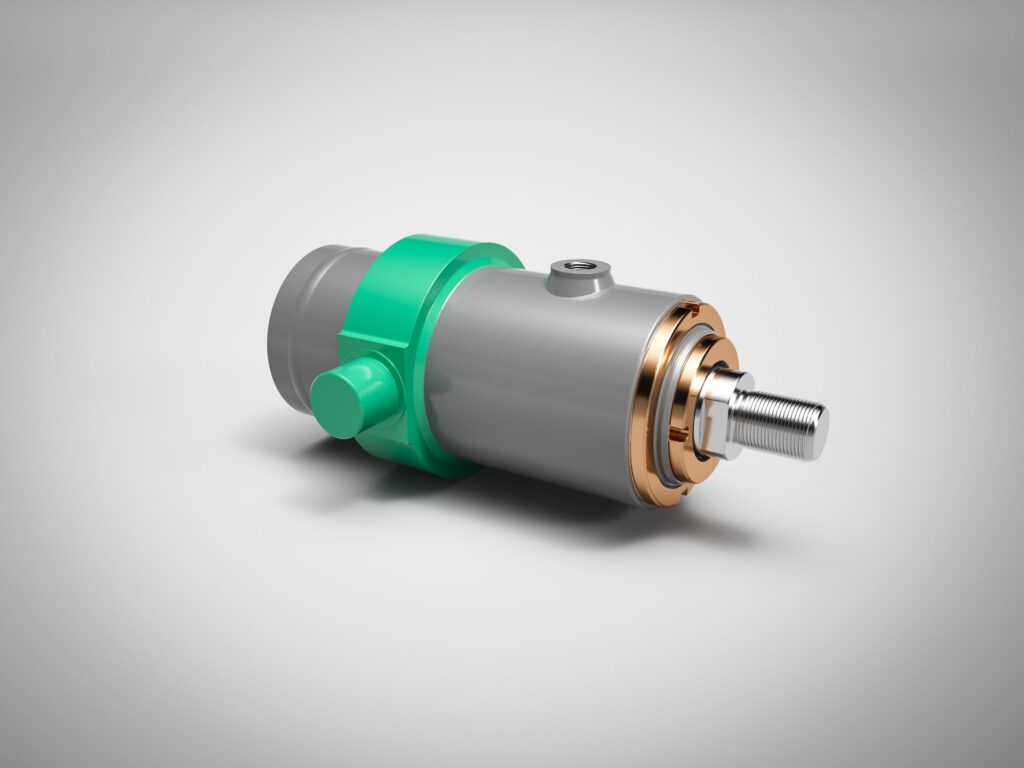

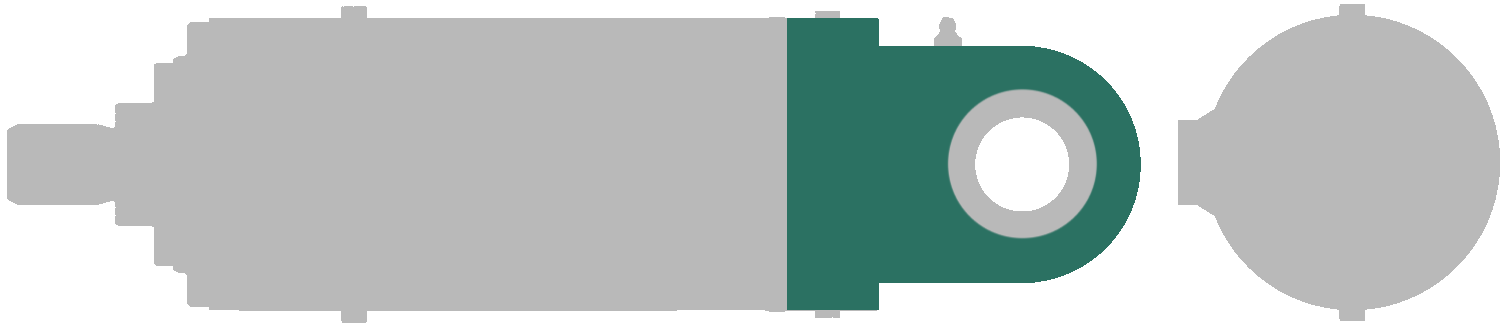

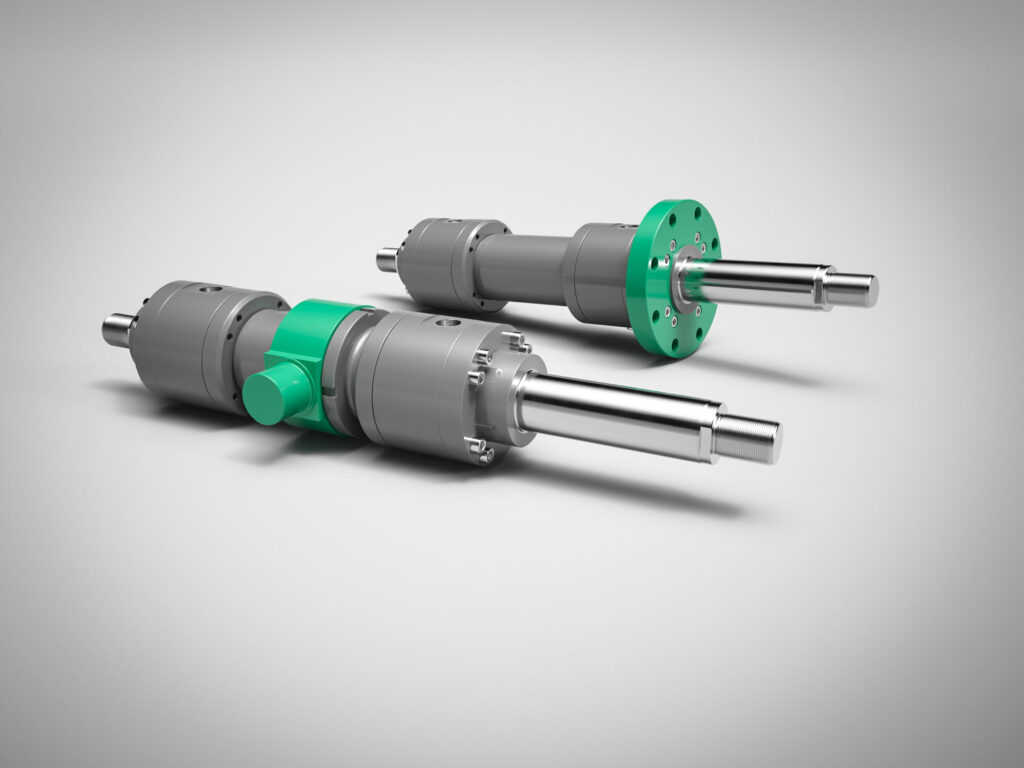

Good to know: These hydraulic cylinders have a piston rod that emerges on either side. Their components essentially correspond to the standardized ZBD 2511 series.

| Nominal pressure: | 250 bar (25 MPa) |

| Static test pressure: | 375 bar (37,5 MPa) |

| Piston diameter: | 40-250 mm (larger than special version) |

| Area ratio j: | 1,6 and 2 |

| Temperature range: | -20…+80 °C |

| Viscosity range: | 10…600 mm²/s |

| Lifting speed: | 0 – 1 m/s depending on seal variant |

| Operating medium: | Mineral oil according to DIN 51524, HFD fluids HFA, HFB and HFC fluids possible through special designs |

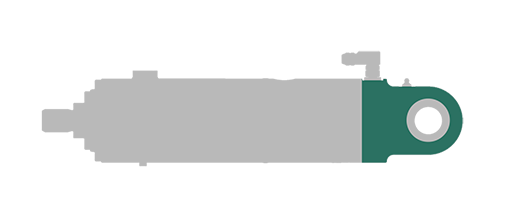

Befestigungsarten

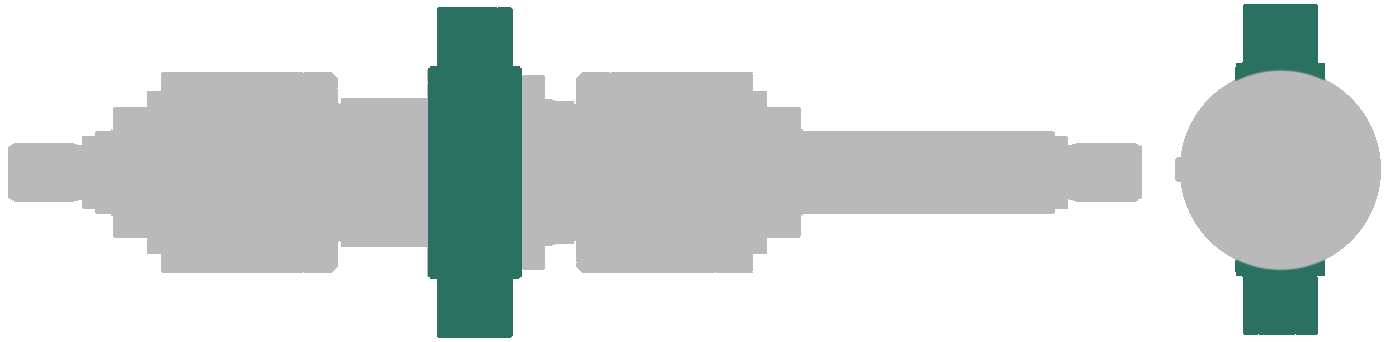

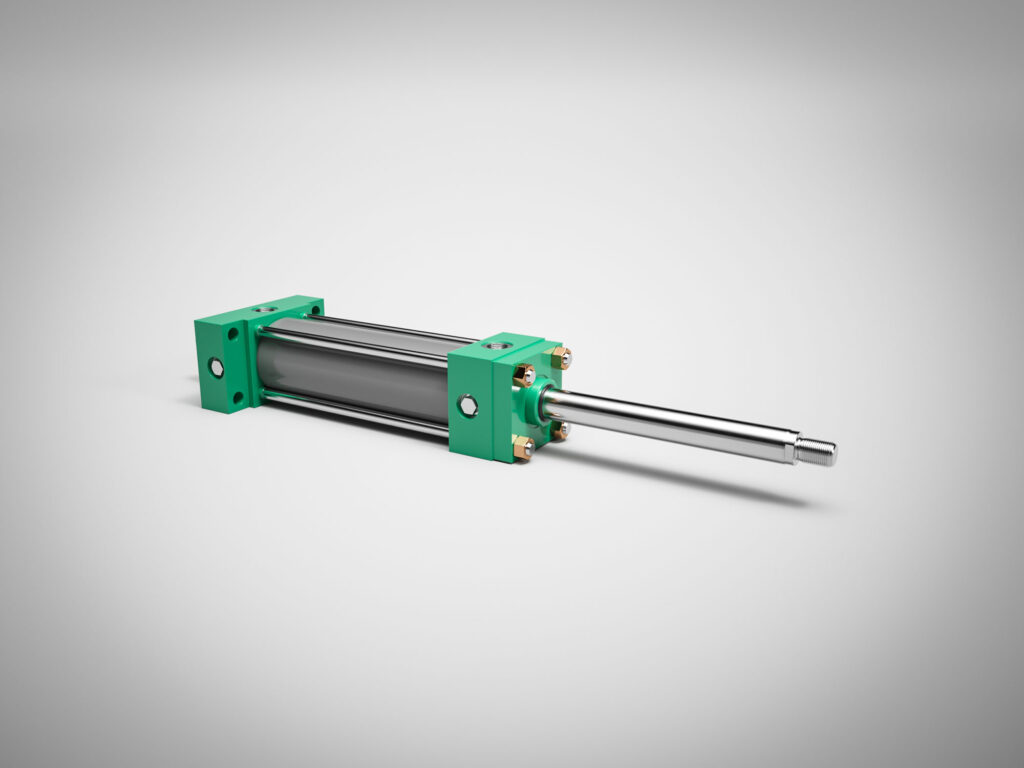

Good to know: These hydraulic cylinders are designed according to the modular principle and have a piston rod emerging on both sides. The cylinder barrel, cylinder head and cylinder base are connected to one another by tie rods – the logical addition to the internationally standardized 160 bar tie rod cylinder series.

Their components essentially correspond to the standardized ZBD 1605 series.

| Nominal pressure: | 160 bar (16 MPa) |

| Static test pressure: | 240 bar (24 MPa) |

| Piston diameter: | 25-200 mm |

| Area ratio j: | 1,25 and 2 |

| Temperature range: | -20…+80 °C |

| Viscosity range: | 10…600 mm²/s |

| Lifting speed: | 0 – 0,5 m/s depending on seal variant |

| Operating medium: | Mineral oil according to DIN 51524, HFD fluids HFA, HFB and HFC fluids possible through special designs |

Befestigungsarten

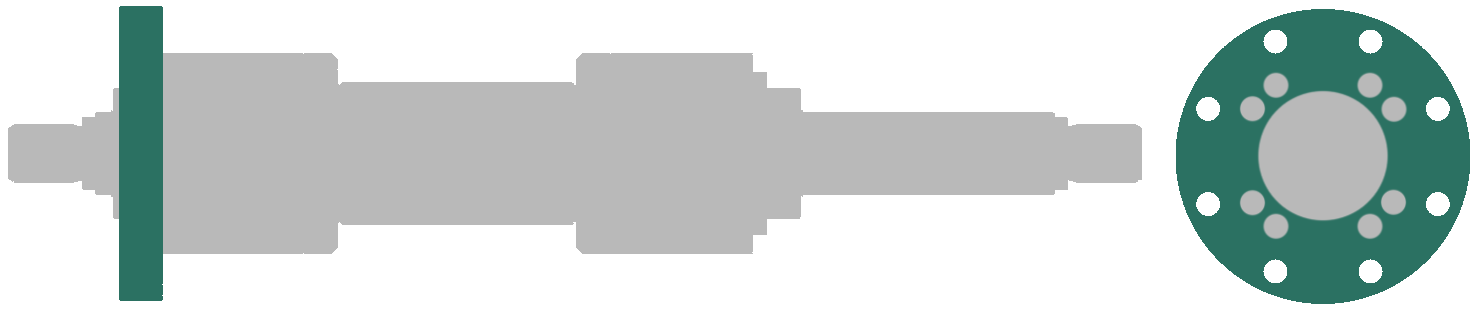

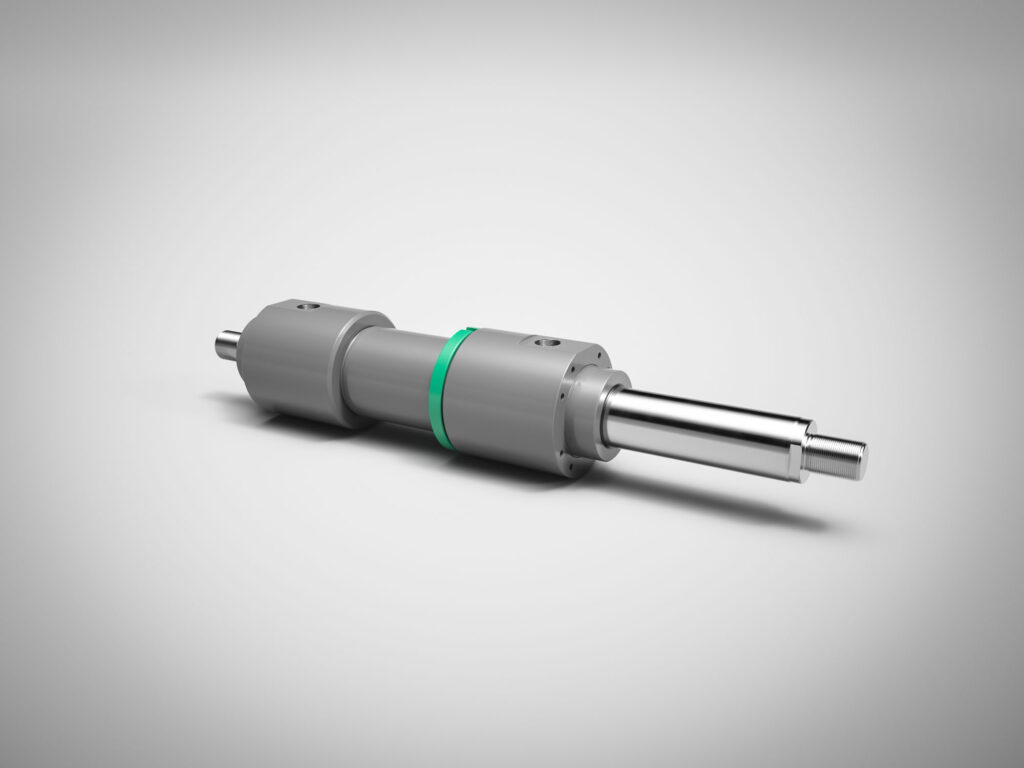

Good to know: These hydraulic cylinders have a piston rod that emerges on either side. Their components essentially correspond to those of the standardized ZBD 1611 series.

| Nominal pressure: | 160 bar (16 MPa) |

| Static test pressure: | 240 bar (24 MPa) |

| Piston diameter: | 25-200 mm |

| Area ratio j: | 1,4 and 2 |

| Temperature range: | -20…+80 °C |

| Viscosity range: | 10…600 mm²/s |

| Lifting speed: | 0 – 1 m/s depending on seal variant |

| Operating medium: | Mineral oil according to DIN 51524, HFD fluids HFA, HFB and HFC fluids possible through special designs |

Befestigungsarten

To ensure that you find the right contact person right away: You can reach your destination quickly by selecting a department: